Most folks don’t sit around debating roofing membranes unless they’re dealing with a soft spot in the ceiling or a roofing contractor’s estimate that suddenly feels like dental surgery with no anesthesia. Flat roofs in New England live a harder life than the brochures suggest — they spend February buried under a wet quilt of snow, April drowning in puddles, and August sizzling like the hood of a black pickup truck on I-93. Andover is no exception, perched in that peculiar weather corridor where nor’easters cut sideways and gutters freeze before sunrise.

So when the roof over your garage, addition, or restaurant finally taps out, the question usually becomes: EPDM, TPO, or PVC? Same family of single-ply membranes, very different personalities

Flat Roofs in Andover: Made for Snow Before Style

Flat and low-slope roofs show up all over Andover — mid-century colonials with a 1960s addition, split-level ranches, two-story duplexes, little commercial plazas, condo buildings, and occasional diners with ventilation units humming through the night.

Unlike pitched roofs where water slides off like rain off a duck’s back, flat roofs behave more like a shallow tray. Snow piles. Water lingers. Sometimes for days. Unsurprisingly, snow load requirements in Massachusetts (per state building codes via Mass.gov) quietly influence how these roofs are designed and retrofitted.

The real villains here aren’t always storms; they’re freeze-thaw cycles around drains, ice dams nibbling at seams, and spring ponding that stretches patience.

EPDM vs TPO vs PVC — Quick Snapshot Before the Deep Dive

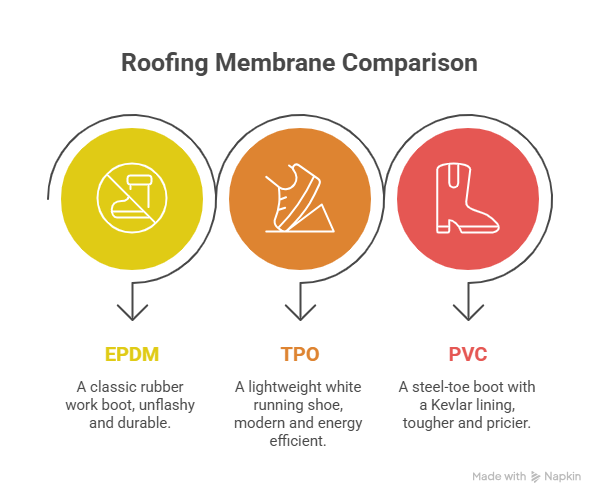

If roofing membranes were shoes:

- EPDM → A classic rubber work boot: unflashy, durable, proven.

- TPO → Lightweight white running shoe: modern, reflective, energy efficient.

- PVC → Steel-toe boot with a Kevlar lining: tougher, pricier, built for abuse.

For Andover’s climate, all three are technically viable — but not for the same reasons, and not for the same buildings.

EPDM: The Black Rubber Veteran

EPDM (short for Ethylene Propylene Diene Monomer) is basically giant synthetic rubber — matte black, flexible, and built to shrug off cold weather. If you’ve ever heard someone refer to a “rubber roof,” they meant EPDM, sometimes linking it to rubber roofing options offered locally through roofing companies.

.png?width=624&height=690&name=_-%20visual%20selection%20(25).png)

Why EPDM Still Wins on Many Residential Projects

- Handles freeze-thaw without turning brittle

- Easy to repair — patches, primers, tapes

- Proven track record in New England climate

- Competitive pricing

- Excellent uptime on 20–30 year roofs

New England roofers often like EPDM for garages, porches, and additions because it plays nice with odd shapes and doesn’t throw tantrums in cold weather. The NRCA also credits EPDM’s success to its flexibility and its ability to handle thermal movement without cracking.

Weak Spots

- Black surface absorbs heat → rooftop temperatures spike in July

- Seams rely on tapes → not as monolithic as heat-welded TPO/PVC

- Less reflective → no “cool roof” benefits in summer

- Puddles after spring melting may test seams over time

EPDM also pairs well when a homeowner is simultaneously exploring roof replacement services for pitched and flat areas together, since it avoids a Frankenstein look.

TPO: The Modern White Roof With Reflective Ambition

TPO (Thermoplastic Polyolefin) arrived later to the party with a very different look. Bright white. Reflective. Clean. When sun hits it, the membrane throws back heat, which Energy.gov classifies under cool roof energy efficiency standards for lowering cooling loads.

Where TPO Makes Sense in Andover

- Larger roofs where AC costs matter

- Condo buildings and mixed-use properties

- Restaurants without grease discharge

- Modern construction where longevity beats pure price

TPO membranes use heat-welded seams, forming a fused bond that doesn’t rely on tapes. When ponding water forms after snow melt, the seams don’t necessarily blink.

The Caveat No One Mentions on Sales Calls

TPO’s Achilles heel isn’t performance — it’s variability. Different manufacturers produce different formulas, and quality control in the early 2000s was uneven. The roofing membrane performance benchmarks reported by industry groups often caution buyers to look at brand history rather than treating TPO as one universal thing.

Andover doesn’t care what brand you choose; the climate will stress test it anyway.

PVC: Tougher, Thicker, and Comfortable With Abuse

PVC (Polyvinyl Chloride) is the higher-end cousin in the family — thicker, stronger against chemicals, and stubbornly resilient around mechanical equipment. If you run a diner, laundromat, or medical facility, PVC typically tops the list.

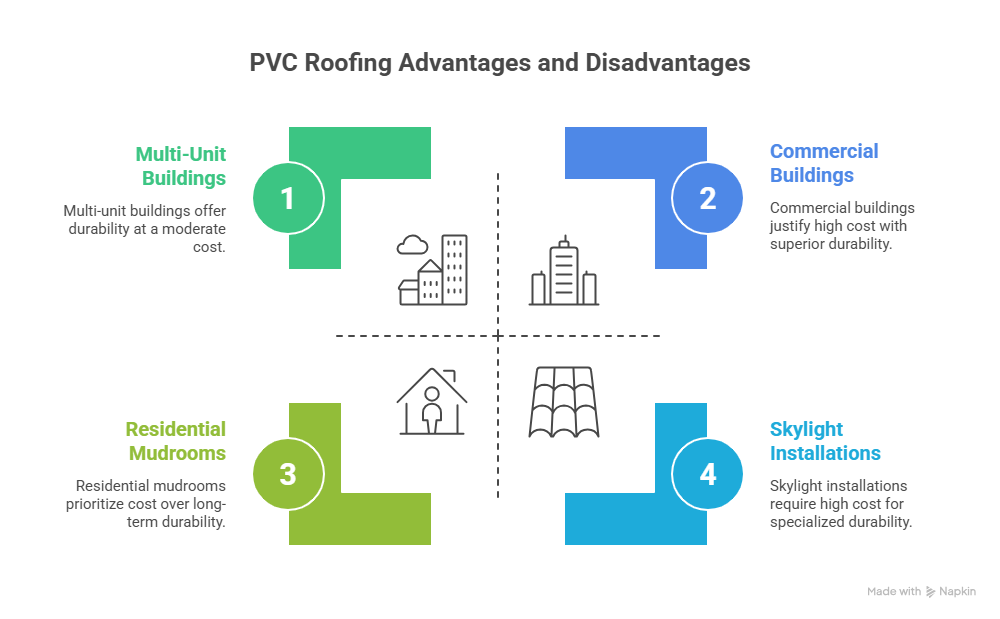

Advantages on New England Properties

- Heat-welded seams (like TPO)

- Superior resistance to ponding water

- Handles rooftop traffic well

- Laughs at grease & exhaust

- Strong option for multi-unit buildings

PVC also shows up on roofs with skylights — a place where installers need good weldability around frames, often paired with skylight repair & installation in older Andover homes.

The Downside

PVC costs more. And while long-term lifespan can justify it on commercial buildings, a tiny mudroom roof might never pay back the premium.

Comparison Table: EPDM vs TPO vs PVC (Andover Conditions)

| Factor | EPDM | TPO | PVC |

|---|---|---|---|

| Material Type | Thermoset | Thermoplastic | Thermoplastic |

| Seams | Taped | Heat-welded | Heat-welded |

| Reflectivity | Low | High | High |

| Cold Weather Flex | Excellent | Good | Good |

| Ponding Water | Fair | Good | Excellent |

| Foot Traffic | Fair | Good | Excellent |

| Chemical/Grease Resistance | Poor | Fair | Excellent |

| Lifespan | 20–30 yrs | 15–25 yrs | 20–30 yrs |

| Cost | $ | $$ | $$$ |

| Best Fit | Residential | Multi-unit | Commercial / Restaurant |

A seasoned roofer might tweak that based on project logistics or insulation specs (which is where R-value and vapor barriers sneak into the conversation).

Energy + Insulation: The Part Contractors Rarely Explain Well

Membranes get all the attention, but insulation does most of the heavy lifting. You could put the fanciest PVC membrane on a roof with lousy insulation and still lose winter heat in a hurry. Building Science Corp makes this point repeatedly when discussing moisture control and R-value strategies in northern climates.

White TPO or PVC can reduce rooftop temps in summer, but New England winters are another creature. Snow sits on the membrane like frosting on a cake, muting reflectivity anyway.

For Andover roofs, insulation matters more than membrane color.

Ponding Water, Ice Dams, and Other Annoyances

After a thaw in March, flat roofs occasionally hold water for 24-48 hours. Insurance research labs like IBHS refer to ponding as a “stress condition” rather than an immediate failure. EPDM handles it, PVC shrugs it off, and TPO does fine when welded properly.

Ice dams can also form around drains and parapets. A good seasonal roof maintenance checklist is boring but beats chasing leaks at midnight.

Cost vs Lifespan vs Building Type (The Real Decision)

Here’s how savvy property owners tend to choose:

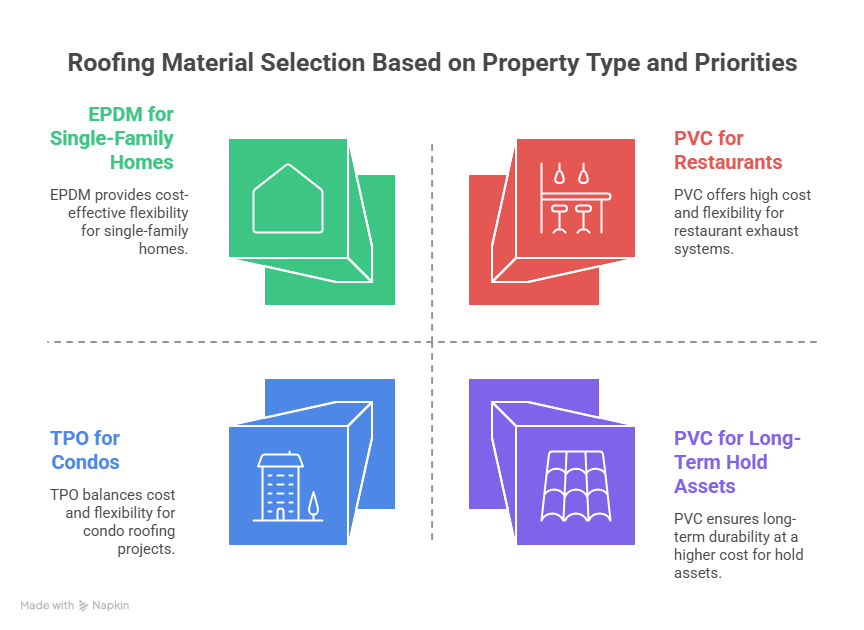

Single-family homes & additions:

→ EPDM wins for cost + flexibility

→ TPO/PVC only if energy savings matter

Condos & multi-family:

→ TPO or PVC due to shared risk

Restaurants & commercial with exhaust:

→ PVC, no contest

Long-term hold assets:

→ PVC or EPDM depending on maintenance appetite

Short-term flips:

→ EPDM often gives best ROI without overspending

It's the same calculus folks use when debating whether to replace gutters during a roof replacement project — do it once, do it cleanly.

Climate Matters More Than Brochures Admit

Andover winters aren’t kind. NOAA weather maps show freeze-thaw cycles spiking from November to March. Thermoplastic membranes (TPO/PVC) remain stable enough, but EPDM’s rubber flexibility makes it particularly forgiving of contraction/expansion cycles.

Local building inspectors sometimes quietly favor membranes with more predictable seam performance on multi-unit properties. The reason is simple: one leak can affect three families instead of one.

FAQ's

Yes. EPDM remains an excellent choice, especially for smaller residential flat roofs and additions. It's flexible in cold weather, has a long track record in New England, and is typically more affordable than PVC. If you don't specifically need a bright white roof, EPDM often delivers the best value.

In many real-world cases, EPDM has a longer and more proven lifespan, often 20–30+ years with proper installation and maintenance. TPO can also perform well (15–25 years), but EPDM's long-term consistency gives it a slight edge for pure longevity.

It can be. PVC is usually worth the investment on roofs that are large, complicated, or critical—such as multi-family buildings, restaurants, medical offices, or properties with lots of rooftop equipment and foot traffic. For a small residential flat roof, EPDM or TPO may be more cost-effective.

Not always. On large roofs with significant AC use, white TPO or PVC can help reduce cooling loads and indoor temperatures. On small residential flat sections, the difference in energy bills may be modest. Roof size, building design, and insulation levels all influence whether a cool roof is actually worth it.